Overview

Moonstone

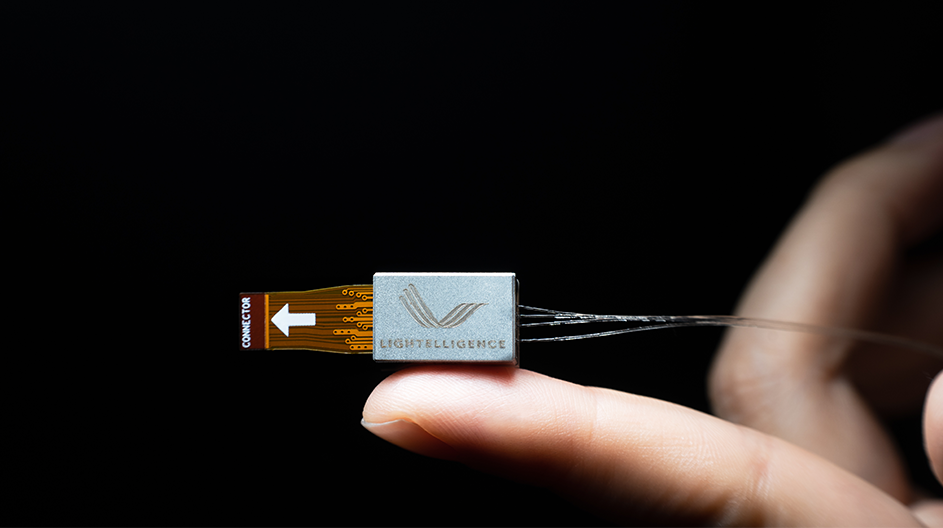

Moonstone™ is a high power, multi-channel, single or multi-wavelength DFB laser source. Compared to butterfly packages, Moonstone™ has a smaller footprint, better operating temperature ranges and is field replaceable with advanced packaging at a much lower price point. Ideal for telecommunications, LIDAR, ethernet switching, along with a broad range of test and sensor equipment.

Replace

4 Butterfly Laser DiodesWith

One Moonstone™Key Technology

FREE-SPACE OPTICAL PACKAGE ASSEMBLY

Moonstone is fabricated using an automation optical packaging assembly process. Off-the-shelf laser chips (with single or multi-wavelengths) are mounted on the carrier and submount using eutectic soldering and die-bonding techniques. The laser chips are connected to the FPC through wire bonding. In the single-wavelength scenario, free-space coupling is employed using lens to focus the laser light into fiber.

In the multi-wavelength scenario, laser light is colllimated into MUX which acts as a beam combiner, and then focused into a single fiber. A TEC is placed underneath to control the temperature of the laser with the aid of thermistor. The base and submount are both materials that have matchable heat conductivity. Moonstone has standard MT ferrule and FPC connector as optical and electrical interfaces, respectively.

Approach

Utilized compact-size high-power DFB laser chip

Based on free-space optical alignment with the guidance of optical design

Customized packaging using eutectic soldering, die-bonding and wire-bonding techniques

Optimized thermal control solution based on TEC

Highlights

Low-cost and low process requirements

Precise thermal control

Low laser-to-fiber coupling loss

Up to 8 wavelengths

High output power

Usage Scenario